Precision Mixing Solutions for Every Industry Need

Mixing solutions involve blending two or more substances to achieve a uniform composition. In industrial applications, mixing is crucial in sectors like chemicals, pharmaceuticals, food processing, and water treatment. Effective mixing enhances product quality, process efficiency, and reaction rates. Equipment such as industrial mixers, agitators, blenders, and tanks are used based on material properties and desired outcomes. Types of mixers include ribbon blenders, paddle mixers, and sigma mixers, each suited for specific applications. Factors like viscosity, density, and temperature influence the choice of mixing solution. Advanced designs ensure consistent performance, scalability, and energy efficiency in both batch and continuous operations.

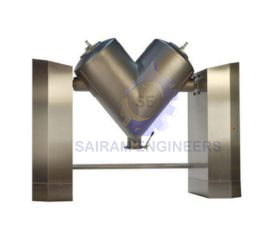

Mixing Solutions Equipment's :

General-purpose equipment used for mixing, blending, and homogenizing materials in chemical, and pharmaceuticals.

Impeller Type Uses rotating impellers to mix liquids efficiently. Paddle Type Gentle mixing for solids and viscous materials.

Conical-shaped rotating blender used for gentle mixing of free-flowing powders and granules.

Eight-sided blender ideal for uniform blending with minimal attrition of fragile particles, often used in pharma.

Mixes dry or wet materials using paddle-shaped blades. Suitable for fragile or heat-sensitive materials.

Rotates a drum or container to blend contents by tumbling action—used for powders and granules.

Heavy-duty mixer with sigma-shaped blades for mixing highly viscous materials like dough, rubber, and adhesives.

Equipped with counter-rotating agitators, ensures thorough mixing, typically used in cosmetics and viscous formulations.

Horizontal mixer with plough-shaped mixing elements, ideal for rapid and high-intensity mixing of powders.

Versatile tank used for liquid-liquid or solid-liquid blending; comes with various agitator types depending on the application.