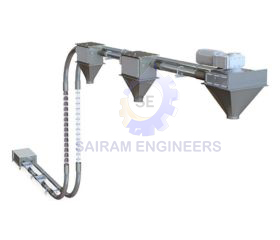

Efficient Solutions for Seamless Material Conveying

Material Conveying Equipment is used to efficiently transport bulk materials from one location to another in industrial processes. These systems are essential in sectors like food processing, pharmaceuticals, plastics, chemicals, and construction. Common types include pneumatic conveyors, screw conveyors, belt conveyors, chain conveyors, and bucket elevators. Pneumatic systems use air pressure to move powders or granules, while mechanical systems like belts and screws are ideal for solids and granules. These conveyors ensure continuous, dust-free, and safe material transfer, enhancing productivity and reducing manual handling. Advanced systems also feature automation for precise control and integration with other process equipment.

Material Conveying Equipment's

Used to move bulk materials like powders and granules in a controlled, enclosed manner using a rotating helical screw blade.

Flexible conveying systems that use discs attached to chains inside a sealed tube, ideal for gentle transport of fragile or mixed materials.

Comprise rollers mounted on frames to transport items manually or via gravity or motor, commonly used for cartons and pallets.

Vertically transport bulk materials using a series of buckets attached to a belt or chain, ideal for handling powders and granules.

Use slats attached to chains to move heavy or bulky items, suitable for high-speed or high-load applications like assembly lines.

Versatile systems using continuous belts to carry products or materials, ideal for long-distance and large volume transport.

Use vibratory motion to move materials along a trough, suitable for fragile, hot, or abrasive materials.

Shaped like a "Z", they are used for elevating materials from one level to another with minimal space usage, often seen in food and packaging industries.